Invest in efficiency: With Nexus Dosing, you save more than just money.

Advanced technology for special requirements in the LSR sector

Coating, Direct Inject, Central Feeding

In the constantly evolving LSR industry, standard solutions often reach their limits. At Nexus Dosing, we recognize these individual challenges of our customers and have also specialized in developing innovative special applications.

Central feeding

The heart of your productionOur central material supply system can easily and efficiently supply any number of dosing systems simultaneously - without additional space requirements.

- Space saving: Thanks to our revolutionary concept, you save significant space in your production area.

- Efficiency: Continuous material supply and a simplified material flow increase production speed.

- User-friendliness: Due to the central positioning of the machines, operation and material change are more ergonomic for the operator, and the paths in the production hall remain clear.

Coating

Revolution in the field of coatingThe importance of silicone coatings is continuously increasing, with applications ranging from airbag coatings to functional textiles. With our coating technology, you are at the forefront of this progress.

- Guaranteed air-free: Our technology guarantees a steady, air-free material flow.

- Precision & Consistency: With Nexus' direct injection, you always achieve the same layer thickness, guaranteed by a stable process.

- Extended functionality: Integrate additives like colors and benefit from uninterrupted feeding thanks to our tandem system.

Direct inject

Maximum output with minimal effortIn the direct injection of low-pressure parts, efficiency is paramount. With Nexus Direct Inject, you are prepared to implement even the most demanding projects.

- Less waste: Guaranteed airbubble-free mixture and an endless injection profile with post-pressure.

- Efficiency increase: Thanks to heated systems that heat the raw material up to 70°C, cycle times are massively shortened.

- Safety & Cleanliness: No degassing path required, minimized risk of contamination, and less maintenance effort.

SPLITNEX from Nexus permanently removes air bubbles in the LSR material. The result? Guaranteed air-free silicone, less wasted material, more stable processes, and minimal mixing deviations.

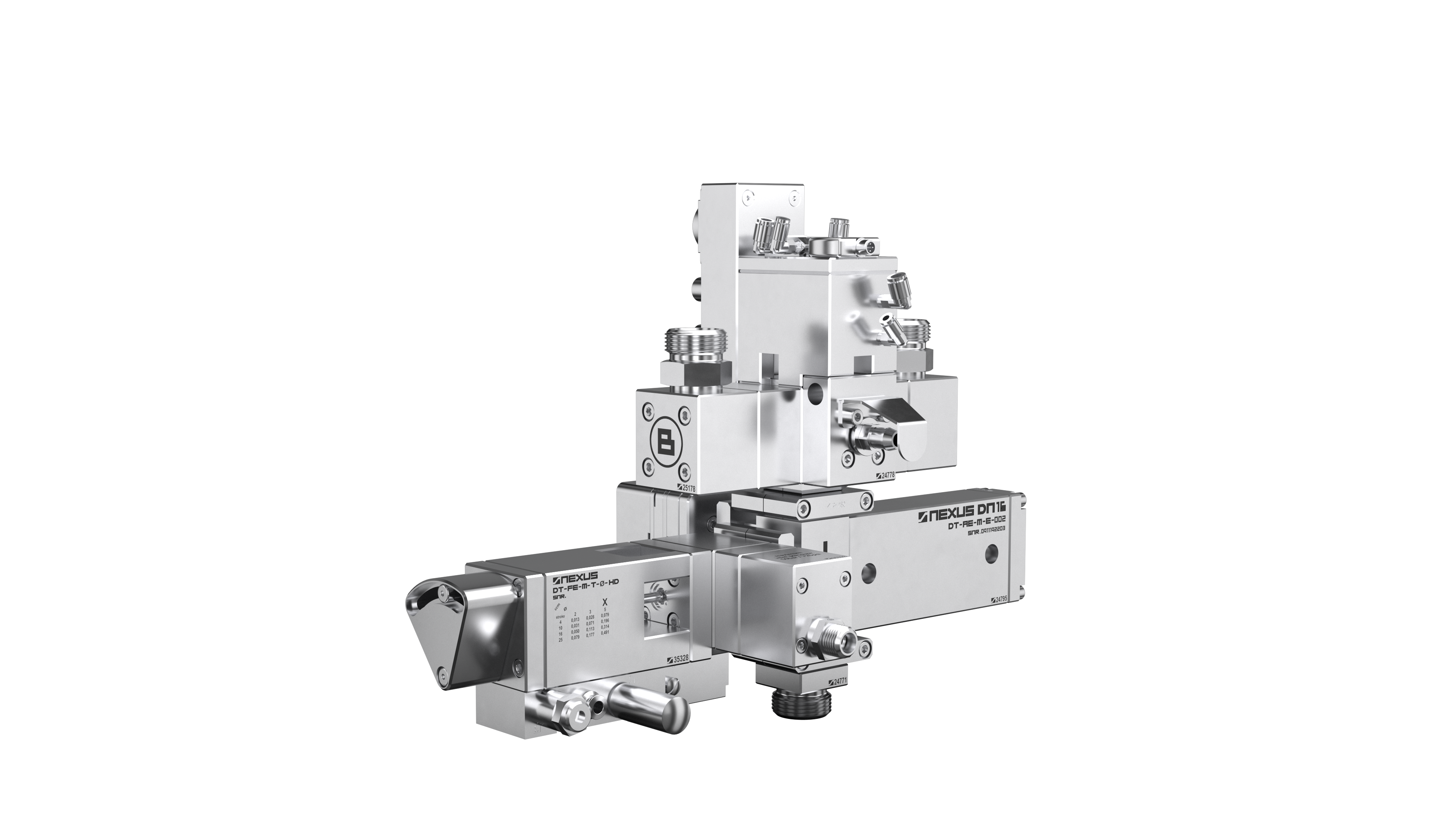

Modular processing unit

- Horizontal static mixer

- Fast color change

- Precise color addition from 0.05% to 20%

- Modular design, configurable according to applications

- Almost unlimited type and number of additives

- Compatible with all Nexus dosing systems

- Fastest cleaning in 20 or 50 min. (without/with color)