Innovative LSR dosing systems of the newest generation

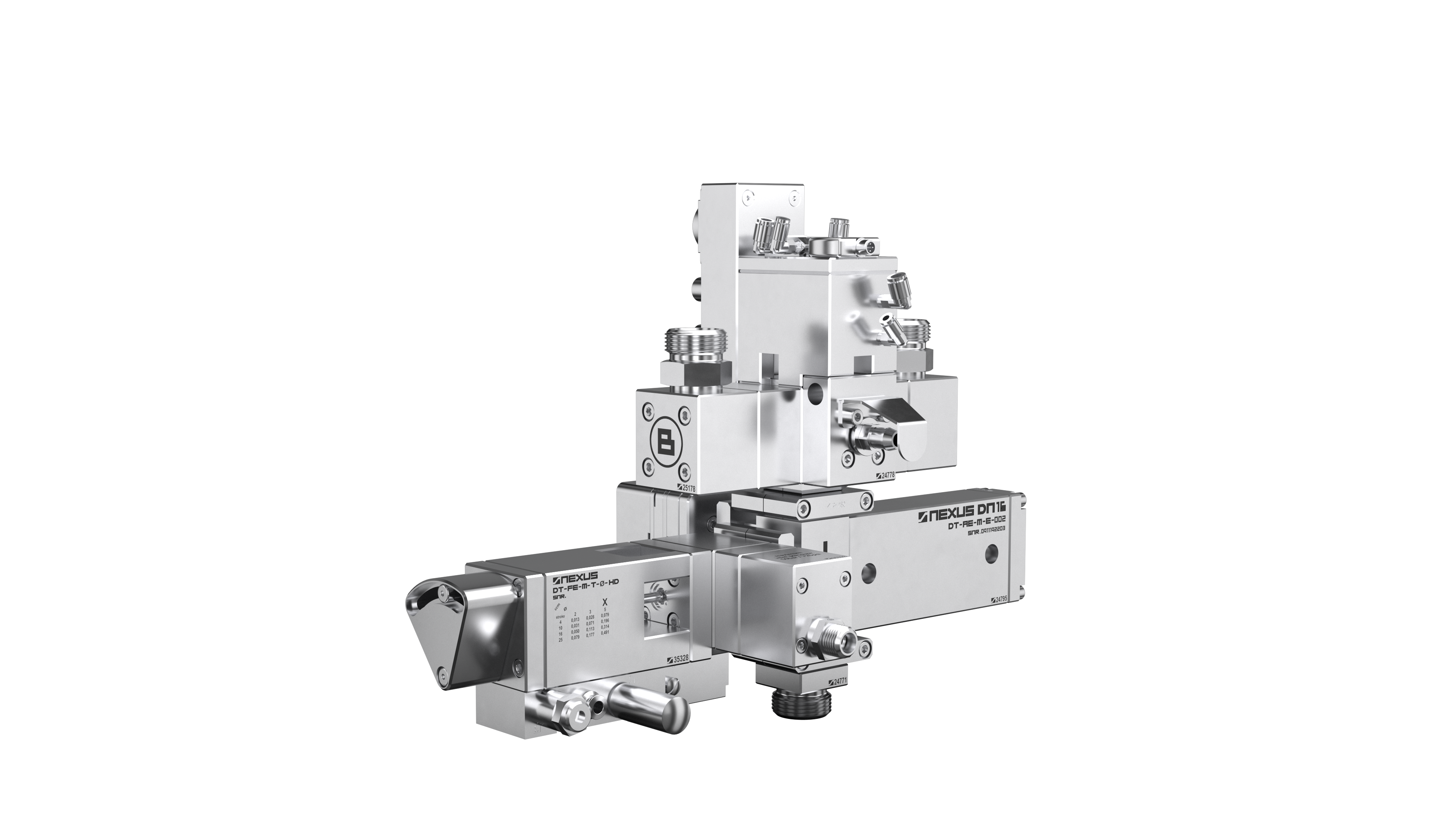

Unique dosing technology

SERVOMIX dosing systems from Nexus ensure the highest material usage on the market thanks to the worldwide unique SPLITNEX technology, guaranteed!

Energy efficiency, usability and cleaning time are unbeatable.

Modular processing unit

- Horizontal static mixer

- Fast color change

- Precise color addition from 0.05% to 20%

- Modular design, configurable according to applications

- Almost unlimited type and number of additives

- Compatible with all Nexus dosing systems

- Fastest cleaning in 20 or 50 min. (without/with color)

SPLITNEX from Nexus permanently separates air bubbles in the LSR material. The result? Guaranteed air-free silicone, less wasted material, more stable processes, lowest mixing deviations.

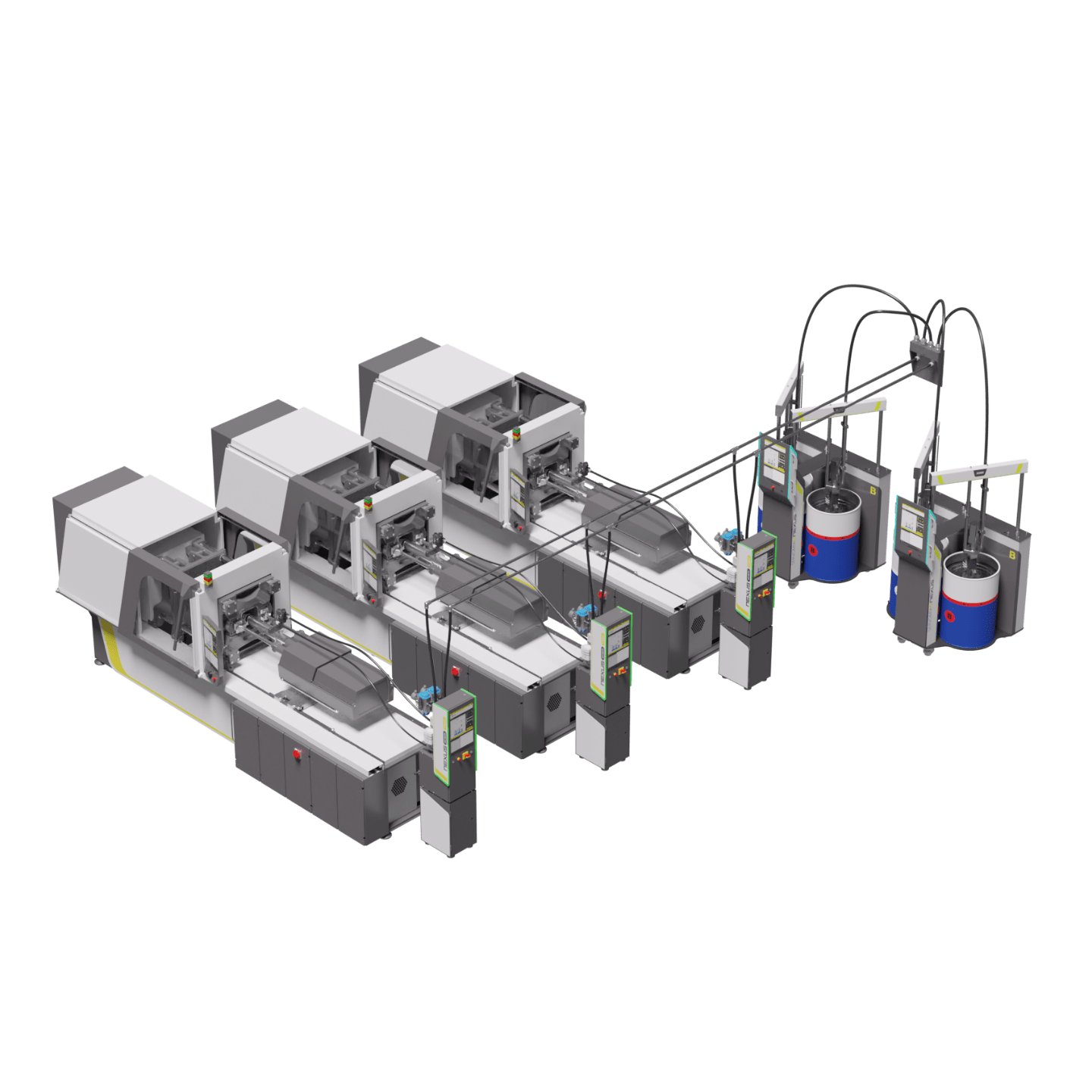

Special applications that impress.

Our customers don't just choose Nexus Dosing; they trust it to fundamentally transform their production. With our specialized special applications like Coating, Direct Inject, and Central Feeding, companies from various industries have optimized their processes and achieved significant cost savings.

Discover how Nexus Dosing enables profound positive changes in production.